![]()

New high-performance functionalised materials

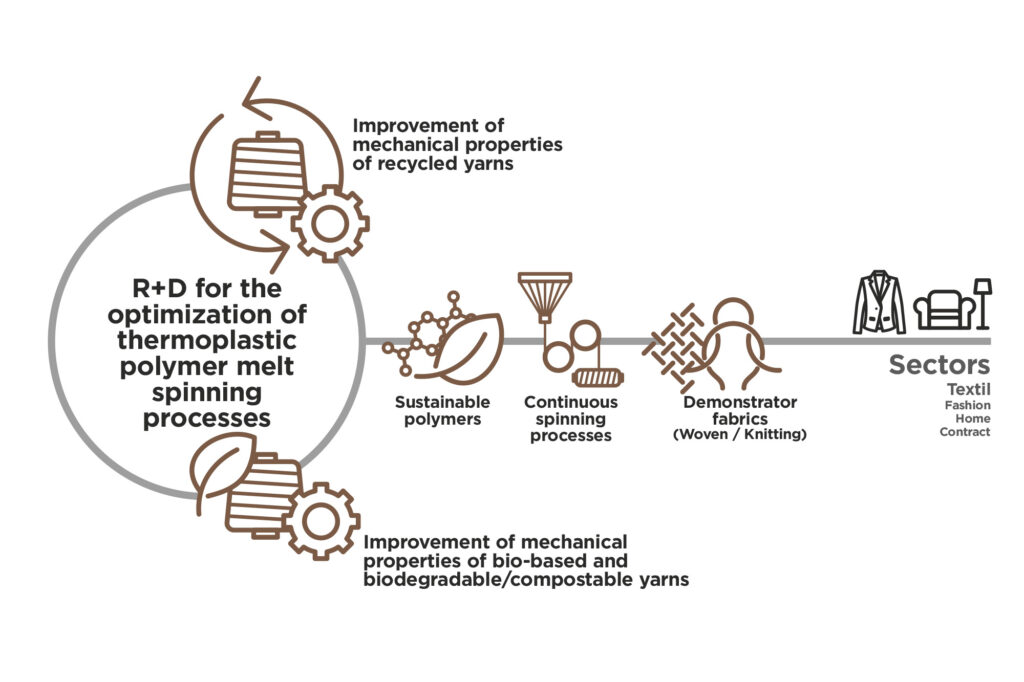

R&D TO OPTIMISE MELT SPINING PROCESSES USING SUSTAINABLE THERMOPLASTIC POLYMERS

ECOMELT 2024

Motivation

The requirements by manufacturers of yarns with sustainable characteristics are becoming more and more demanding and this project will optimise the melt spinning processes to improve the physical and mechanical properties of recycled, bio-based and biodegradable/compostable polymers.

The overall aim is to expand the range of competitive sustainable products with high added value, offering companies in the Valencia Region different alternatives to adapt their processes and products to the new environmental requirements such as EU Directive 2018/851, which has established a new regulation in which member states will be obliged to ensure the selective collection of textile waste before 1 January 2025.

Objectives

- Improve the mechanical properties of yarns obtained from recycled, bio-based, compostable and or biodegradable polymers by optimising spinning processes to minimise the environmental impact produced by the TEXTILE sector.

- To Improve the mechanical properties of threads obtained from recycled polymers by optimizing “Spunmelt” spinning processes.

- To improve the mechanical properties of yarns from bio-based and compostable/biodegradable polymers, through by optimizing spunmelt spinning,

- Develop demonstrator fabrics from the sustainable yarns and validate the results.

Value and competitive advantage

-

Sustainable yarns made from recycled and bio-based polymers, applied to conventional processes (spinning and texturizing).

-

High tenacity in recycled yarns and good properties in bio-based yarns.

-

Innovation in BioPBS nonwovens with fine weights, expanding their use in various applications.

Obtained results

Recycled Polymers

- Development of recycled monofilament yarns from various materials using stable processes.

- Production of multifilament yarns from recycled polyester, polyamide, and polyethylene.

- Texturizing of recycled polyester yarns to improve volume, strength, and feel.

- Manufacturing of woven fabrics from recycled polyester yarns to evaluate their performance.

Bio-based and Biodegradable/Compostable Polymers

- Development of BioPBS monofilament yarns using stable processes.

- Production of multifilament yarns from BioPBS, PLA, SCPLA, PHA, and BioPA.

- Texturizing of BIO polyamide yarns using DTY and ATY technologies to improve volume, strength, and feel.

- Development of BioPBS nonwoven sheets using Meltblown technology.

- Manufacturing of woven fabrics from BioPA yarns to evaluate their performance and properties.

Grant number: IMAMCA/2024/6

Programme: Plan of non-economic activities 2024

Period of execution: January 2024 – December 2024

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

Project supported by the Conselleria Conselleria de Innovación, Industria, Comercio y Turismo de la Generalitat Valenciana, through IVACE

CONTACT US

Do you want to contact us? Click on the button and write to us.

R&D AREAS

NEWS

AITEX will be present at the new edition of In-Cosmetics 2025, which will be held from 8 to 10 April in Amsterdam. Find out about our laboratory testing and R&D services. Stand 5D12.

The technology centre AITEX and the investment vehicle REDIT Ventures create, in co-investment, the new company Honeytex, focused on the manufacture of advanced materials based on honeycomb cores.

The European LIFE ANHIDRA project will reduce the environmental footprint of one of the industries with the highest global water consumption.