![]()

New high-performance functionalised materials

R&D OF HIGH-PERFORMANCE TEXTILES FOR SECTORS WITH EXTREME TECHNICAL REQUIREMENTS

HIGHTEX

Motivation

There is a huge variety of technical products available for sectors with exacting technical demands and highly specific requirements. The need for optimum performance from these products makes them subject to rigorous quality standards and demanding regulations.

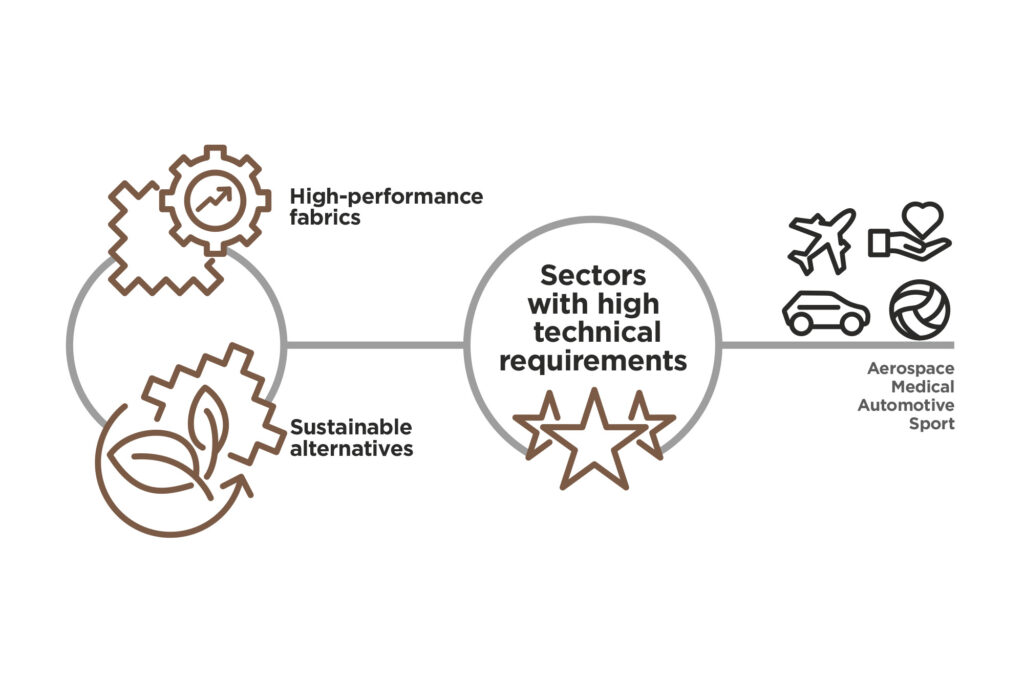

This project aims to develop alternatives using sustainable, recycled or natural materials to create a final product with similar characteristics to those obtained with standard technical yarns.

Objectives

- Provide sectors with technical requirements such as the aerospace, medical, automotive and sports industries, with high performance fabrics that meet their demands.

- Seek sustainable alternatives to improve sustainability in the value chain and production efficiency to create a more eco-efficient product.

Value and competitive advantage

-

Manufacturing of recycled yarns with high tenacity and elongation as a sustainable technical alternative.

-

Improvement in texture, volume, and mechanical resistance through innovative techniques such as ATY, DTY, and braiding.

-

Natural fibers and sustainable matrices for lightweight and durable structural applications.

-

Innovative, sustainable, and economically viable solutions for demanding industries.

Obtained results

Yarn Production

- Processing of thermoplastic materials through multifilament melt spinning. The base materials used include recycled polyester (rPET), recycled polypropylene (rPP), and polyamide 12 (PA12).

- Air texturing (ATY) and false-twist texturing (DTY) tests performed on multifilament yarns, achieving greater volume, improved appearance, softness, and smooth texture through fiber interlacing.

Yarn Hybridization

- Production of innovative yarns by combining various raw materials, including flat tapes produced via braiding, known for their high mechanical resistance and linear density, ideal for specialized weaving processes.

Weaving Work

- Development of technical woven fabrics using sustainable materials and fabrics made from flat tapes through braiding.

Composites with Advanced Properties

- Achieved through thermoforming processes and resin infusion.

Grant number: IMAMCA/2024/6

Programme: Plan of non-economic activities 2024

Period of execution: January 2024 – December 2024

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

Project supported by the Conselleria Conselleria de Innovación, Industria, Comercio y Turismo de la Generalitat Valenciana, through IVACE

CONTACT US

Do you want to contact us? Click on the button and write to us.

R&D AREAS

NEWS

AITEX will be present at the new edition of In-Cosmetics 2025, which will be held from 8 to 10 April in Amsterdam. Find out about our laboratory testing and R&D services. Stand 5D12.

The technology centre AITEX and the investment vehicle REDIT Ventures create, in co-investment, the new company Honeytex, focused on the manufacture of advanced materials based on honeycomb cores.

The European LIFE ANHIDRA project will reduce the environmental footprint of one of the industries with the highest global water consumption.