![]()

New high-performance functionalised materials

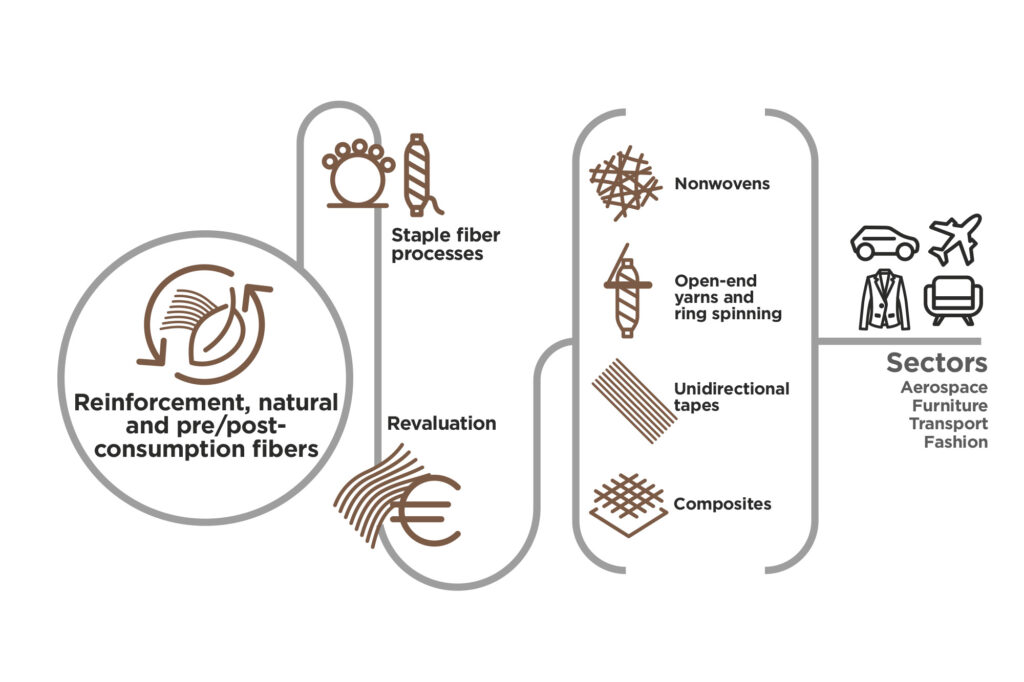

CIRCULARITY IN REINFORCING TECHNICAL FIBRES TO ENSURE REVALUATION IN TEXTILE INTERMEDIARIES AND TO REUSE NATURAL AND CONVENTIONAL FIBRES TO ADAPT THEM TO CUT FIBRE SPINNING

FIBERSPIN

Motivation

Staple fibre spinning has evolved over time to address environmental challenges. The ability to recycle fibres and the adoption of more sustainable technologies in spinning are contributing to reduce the environmental impact of the textile industry. The business community of the Valencia Region is particularly interested in adapting its processes to the new staple fibre blends as their characteristics make it difficult to reuse conventional parameters, meaning that optimum processability must be studied on a case-by-case basis.

This project focuses on pre- and post-consumer waste, one of the most urgent problems to be solved in the textile industry. Currently, of the tiny percentage of fibres that are recycled, an even more insignificant part of those is recycled through staple fibre technologies. The complex process of fibre preparation and parallelisation has inhibited the use of carding technology.

Objectives

- Improve the processability of new blends and materials used in staple fibre technologies.

- To revaluate post-consumer composites by removing resins with pyrolysis..

- To create nonwoven fabrics from recycled reinforcement fibre with high-performance thermoplastic matrix, achieving more sustainable textiles without losing mechanical properties.

- To develop and produce hybrid yarns and fabrics from recycled reinforcement fibre (rCF) with thermoplastic commodity matrices and high performance thermoplastic matrices.

- To optimise punching and calendering technologies for use in nonwovens of natural fibres and recycled technical fibres.

Value and competitive advantage

-

Improve the quality of recycled carbon yarn.

-

New market opportunities for flax, jute, and pineapple fibers, with potential applications in the composite parts sector.

-

Enhancement of recycled yarn quality and the possibility of expanding materials suitable for textile use.

Obtained results

-

Increase in the percentage of recycled carbon fibers in hybrid yarns made from chopped fibers and thermoplastic filaments. Hybridization with flame-retardant materials, such as PPS, for use in strategic sectors.

-

Revalorization of fiberglass using chopped fiber technologies to create hybrid nonwovens with a high percentage of this fiber.

-

Shaping of thermoplastic composites with hybrid rCF yarns, improving their mechanical properties for applications in load-bearing elements.

-

Spinning of natural fibers with reduced counts using conventional ring and multi-balloon spinning techniques.

-

Revalorization of pre-consumer denim fibers through chopped fiber spinning processes.

Grant number: IMAMCA/2024/6

Programme: Plan of non-economic activities 2024

Period of execution: January 2024 – December 2024

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

Project supported by the Conselleria Conselleria de Innovación, Industria, Comercio y Turismo de la Generalitat Valenciana, through IVACE

CONTACT US

Do you want to contact us? Click on the button and write to us.

R&D AREAS

NEWS

AITEX will be present at the new edition of In-Cosmetics 2025, which will be held from 8 to 10 April in Amsterdam. Find out about our laboratory testing and R&D services. Stand 5D12.

The technology centre AITEX and the investment vehicle REDIT Ventures create, in co-investment, the new company Honeytex, focused on the manufacture of advanced materials based on honeycomb cores.

The European LIFE ANHIDRA project will reduce the environmental footprint of one of the industries with the highest global water consumption.