![]()

High value-added solutions for strategic markets

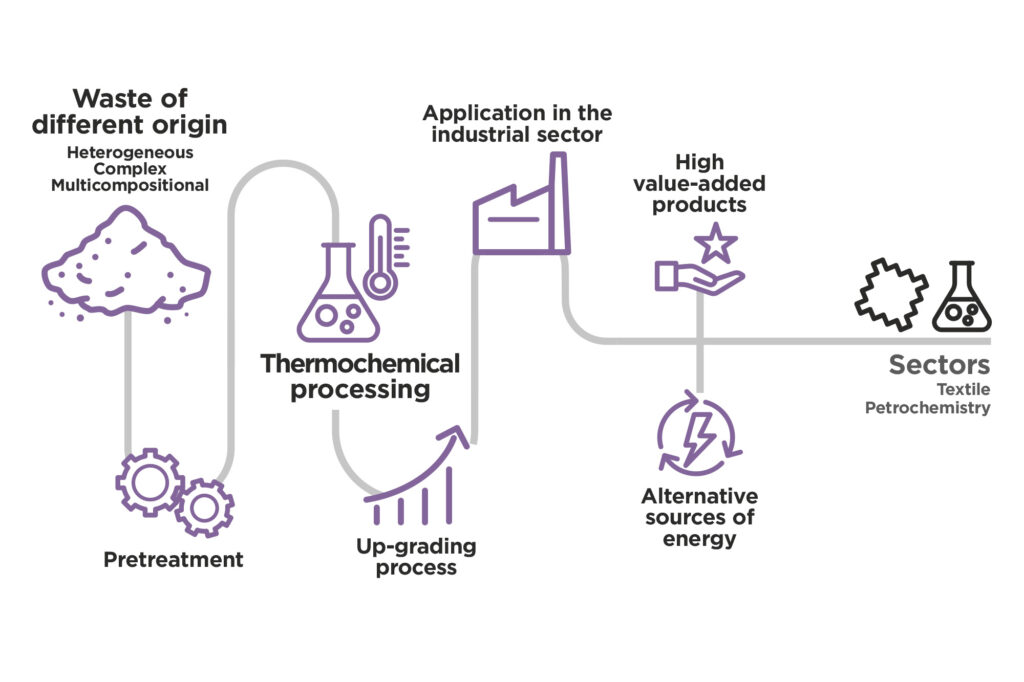

VALUATION OF TEXTILE WASTE AND BIOMASS VIA A THERMOCHEMICAL APPROACH

WASTE2CHEMVALUES 2024

Motivation

The project is framed within the lines stipulated in the European Green Pact to reduce greenhouse gas emissions in the EU and achieve climate neutrality by 2050. This requires a progressive substitution of fossil fuels by cleaner forms of energy, and of synthetic products of fossil origin, such as organic chemicals and polymers, by products synthesised from raw materials of non-fossil origin, thus promoting circular processes in industrial environments.

In this context, the present project will address the aforementioned issue by improving the energy efficiency of industrial processes, prioritizing the textile sector due to its significant environmental impact (greenhouse gas emissions, intensive use of fossil fuels, etc.); while also studying the use of waste to obtain chemicals of interest for the textile industry itself as well as for adjacent sectors.

Objectives

- To process a large volume of waste through various thermochemical processes and to develop upgrading processes of the secondary streams to obtain chemical products of interest.

- To overcome the current challenges of processing complex organic polymers (in terms of selectivity and separation of products of interest) to obtain added value products from biomass waste.

Value and competitive advantage

-

Obtaining fixed carbon in HTC, useful for contaminant adsorption.

-

Production of compounds from HTL applicable in biodiesel, polymers, and cosmetics.

-

MOFs have high value for gas storage, such as H2, which is key for clean energy sources.

-

Lignin extracts with high antioxidant capacity, applicable as lignocellulosic filler in polymeric materials to improve properties.

-

Valorization of lignin as an alternative for waste management, currently lacking a revaluation option.

Results obtained

Hydrothermal:

- Textile waste processed by hydrothermal pyrolysis (HTC) improved fixed carbon, useful for contaminant adsorption applications.

- In hydrothermal liquefaction (HTL), high-value compounds were obtained, applicable in biodiesel, polymers, and cosmetics.

MOFs:

- Shredded textile waste was used to create MOFs with high porosity, suitable for gas storage like H2.

- The process contributes to the circular economy by reusing textile waste to produce sustainable materials.

Antioxidant Capacity Determination:

- UV radiation with a catalyst achieved high lignin degradation, but the generated products did not show antioxidant properties.

Lignin Extraction with Solvents:

- Extractions were carried out with solvents of different polarities, achieving good yields and establishing the viability of sequential extractions.

- The extracts demonstrated antioxidant properties and UV radiation protection.

Grant number: IMAMCA/2024/6

Programme: Plan of non-economic activities 2024

Period of execution: January 2024 – December 2024

Status: Finished

More information: PLAN OF ACTION

Entity: IVACE

Project supported by the Conselleria Conselleria de Innovación, Industria, Comercio y Turismo de la Generalitat Valenciana, through IVACE

CONTACT US

Do you want to contact us? Click on the button and write to us.

R&D AREAS

NEWS

AITEX will be present at the new edition of In-Cosmetics 2025, which will be held from 8 to 10 April in Amsterdam. Find out about our laboratory testing and R&D services. Stand 5D12.

The technology centre AITEX and the investment vehicle REDIT Ventures create, in co-investment, the new company Honeytex, focused on the manufacture of advanced materials based on honeycomb cores.

The European LIFE ANHIDRA project will reduce the environmental footprint of one of the industries with the highest global water consumption.