![]()

New high-performance materials and functionalities

R&D OF COMPLEX TEXTILE STRUCTURES FOR EXTERIOR ARTICLES

COMPEX

Motivations

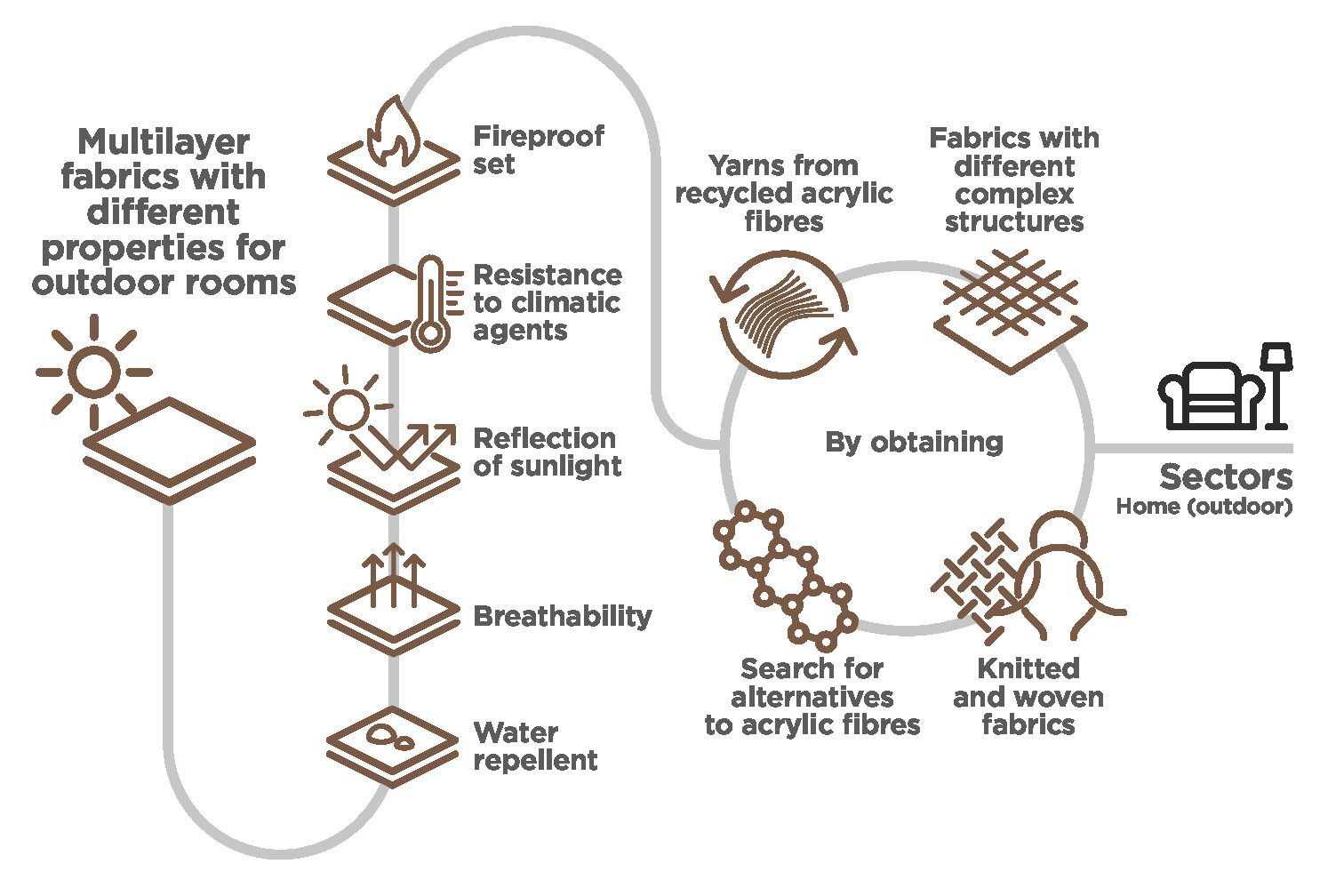

The core of the COMPEX project is to develop outdoor fabrics ideally suited to the create prototype awnings, pergolas and blinds using recycled acrylic yarns and other materials to create climate-efficient areas that are resistant to the action of climatic agents. Recycling materials, saving energy and reducing the consumption of resources are essential aspects for manufacturers today, so the creation of thermally efficient rooms using yarns from recycled virgin materials increases profitability and sustainability.

Objectives

Develop fabrics for complex structures with all the technical qualities suitable for outdoor energy efficiency.

The project will focus on achieving certain specific objectives that will facilitate the core objective set out above:

- Create yarns from recycled acrylic fibres.

- Carry out a comparative study of the results obtained from yarns made from recycled acrylic material compared to those made from virgin acrylic.

- Create fabrics with different complex structures that combine the technical properties required of outdoor fabrics, and optimised for the desired use.

- Create knitted and woven fabrics to compare both types for outdoor fabrics.

- Search for alternatives to acrylic fibres.

- Develop prototypes using the fabrics developed in the project.

- Finish the resulting fabrics.

- Characterise the resulting fabrics.

- Disseminate and transfer the results of the project to companies and the general public according to the project’s dissemination and transfer plans.

Valor y ventaja competitiva

-

The use of monomaterials favors recyclability and promotes a circular economy.

-

Fabrics adapted to various applications (architecture, construction, and exterior design) through customizable technical properties according to needs.

-

A combination of technical innovation with industrial scalability, ensuring the feasibility and competitiveness of products in the market.

-

Improvement of shell quality by manufacturing a metal mold for plastic injection.

-

Cost reduction in mass production of parts.

-

Easily transportable and wireless training systems.

Results obtained

-

Improvement of the technical characteristics of fibers by combining different types of threads through twisting and winding.

-

Research and optimization of textile structures to combine multiple technical properties into a single fabric, both individually and collectively.

-

Division of the weaving process into two phases: first, individual properties were optimized, then combined into hybrid fabrics. Various threads, such as polyester and threads with FIR, bioceramic, and aluminized properties, were used to develop high-quality fabrics.

-

Creation of multilayer fabrics with combinations of various properties.

-

Production of calendered finishes to improve cohesion, feel, and appearance of fabrics, especially those with coated threads, resulting in samples suitable for outdoor products.

Grant number: IMDEEA/2023/68

Programme: Grants to CV technology centres for R&D projects in cooperation with the private sector

Period of execution: January 2023 – December 2024

Status: Finished

Entity: IVACE

This project has the support of the Conselleria d’Economia Sostenible, Sectors Productius, Comerç i Treball de la Generalitat Valenciana, through the IVACE, and is co-financed by the FEDER funds (European Regional Development Fund) of the European Union, within the FEDER Operational Program of the Comunitat Valenciana 2021-2027.

CONTACTE CON NOSOTROS

¿Quiere contactar con nosotros? Pinche en el botón y escríbanos.

ÁREAS DE I+D

NOTICIAS

AITEX will be present at the new edition of In-Cosmetics 2025, which will be held from 8 to 10 April in Amsterdam. Find out about our laboratory testing and R&D services. Stand 5D12.

The technology centre AITEX and the investment vehicle REDIT Ventures create, in co-investment, the new company Honeytex, focused on the manufacture of advanced materials based on honeycomb cores.

The European LIFE ANHIDRA project will reduce the environmental footprint of one of the industries with the highest global water consumption.