LABORATORY OF

LITHIUM-ION

BATTERIES

LABORATORY OF LITHIUM-ION BATTERIES

ANALYSE THE PERFORMANCE OF LITHIUM BATTERIES UNDER EXTREME CONDITIONS TO GUARANTEE THEIR SAFETY IN TRANSPORT AND ELECTRONICS

In recent years, lithium-ion batteries have become widespread as an energy source in many industries, from automotive to consumer electronics. Their ability to store large amounts of energy in a small space has driven their integration into lightweight electric vehicles such as bicycles, scooters and motorbikes, as well as mobile devices, portable tools and everyday products

However, this same energy capacity, coupled with the unstable nature of lithium, has led to growing safety concerns. This is compounded by the fact that, in many cases, batteries have not been tested to simulate their actual use or transport. Against this backdrop, AITEX Spain’s newest new lithium battery analysis laboratory to provide an advanced technical service to guarantee the safety, reliability and sustainability of these devices

CAPABILITIES OF THE LITHIUM-ION BATTERY LABORATORY

-

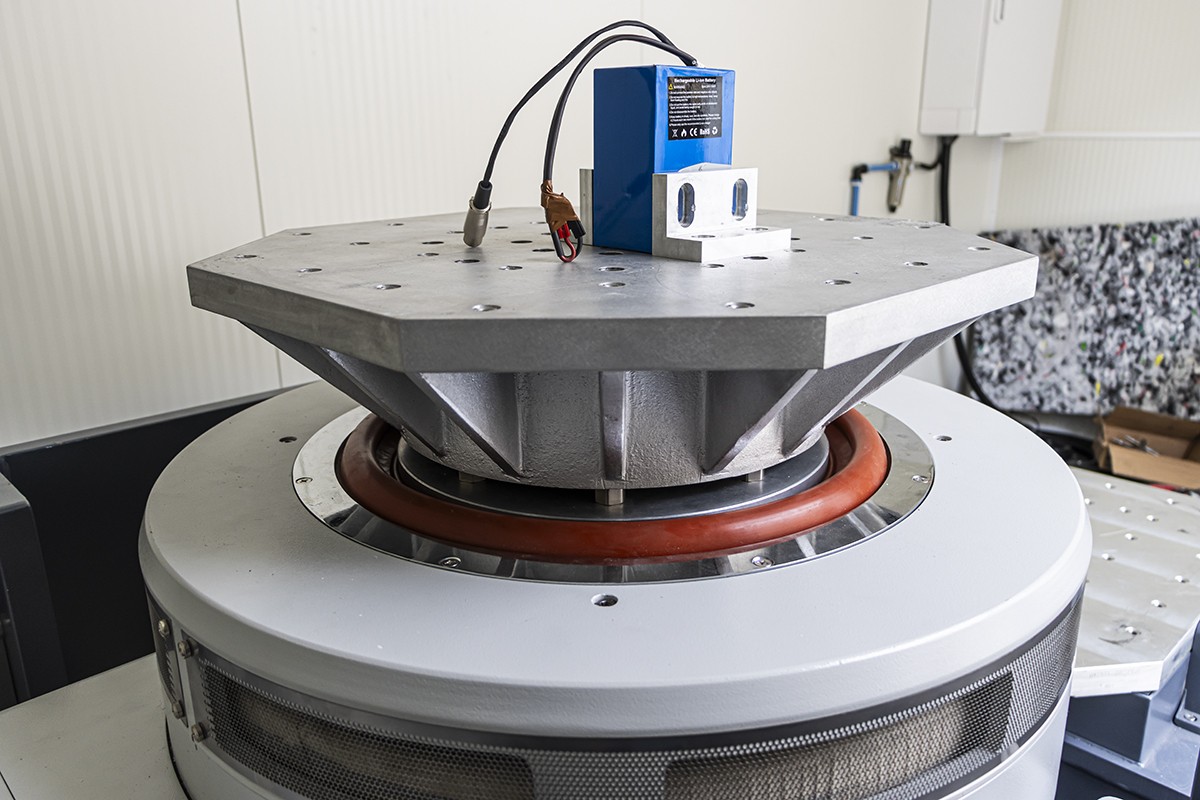

Laboratory equipped with advanced technology for the analysis of lithium-ion batteries under extreme conditions of use and transport.

-

Facilities designed to test small and medium sized drum sets

-

Technical tests that simulate critical scenarios: overload, vibration, impacts, short circuits or thermal changes, among others.

-

Technical team specialised in electrical and energy safety, constantly updated to respond to the new challenges of the sector.

LABORATORY TESTS ON LITHIUM BATTERY ANALYSIS

ENVIRONMENTAL AND TECHNICAL TESTING

Evaluation of battery performance under adverse environmental conditions that may cause instability or premature degradation.

> Altitude: battery performance in low atmospheric pressure conditions.

> Thermal gradient: response to extreme temperatures or sudden changes in temperature

MECHANICAL AND TRANSPORT TESTS

Simulation of physical and dynamic stresses that may occur during daily use or transport logistics.

> Vibration: evaluation of deterioration due to exposure to constant vibration, such as during transport or use in vehicles.

> Impacts and shocks: simulation of falls or sudden braking

> Crushing: behaviour when an object falls on the battery or the battery is compressed.

ELECTRICAL AND FUNCTIONAL SAFETY TESTING

Analysis of the electrical integrity of the battery and its reaction to power failure or overload situations.

> Short-circuit: analysis of the risk in the event of internal or external electrical faults

> Overload: analysis of the stability against electrical overloads

> Failure response: detection of risks of combustion, thermal leakage or emission of toxic gases

REQUEST MORE

INFORMATION

If you wish to receive more information, please fill in and send the form, and we will contact you as soon as possible.

LABORATORY TO ANTICIPATE SECURITY RISKS AND VALIDATE TECHNOLOGIES

When lithium comes into contact with air or reacts in an uncontrolled manner, extremely aggressive combustion can result. This risk not only compromises end-user safety, but also has environmental implications. A battery that fails or catches fire can release toxic gases and represent a hazardous waste that is difficult to manage, in addition to the thermal emission that would be difficult to control.

The absence of proper testing protocols may extend the life of defective products on the market or prevent rigorous technical evaluation before they are placed on the market. With this new laboratory, AITEX can help reduce dependence on external laboratories and reinforce battery quality control. This commitment also aligns with the objectives of energy transition and sustainable mobility, by facilitating the validation of safe and efficient technologies that extend the useful life of products and minimise their environmental impact.

LABORATORIES

We carry out tests, characterisation and quality control of products in compliance with technical requirements and international standards.

OTHER AREAS OF AITEX

AITEX provides different types of services aimed at companies that develop products for the markets of the different areas and sectors of application. These services to companies fall into the following areas of action.